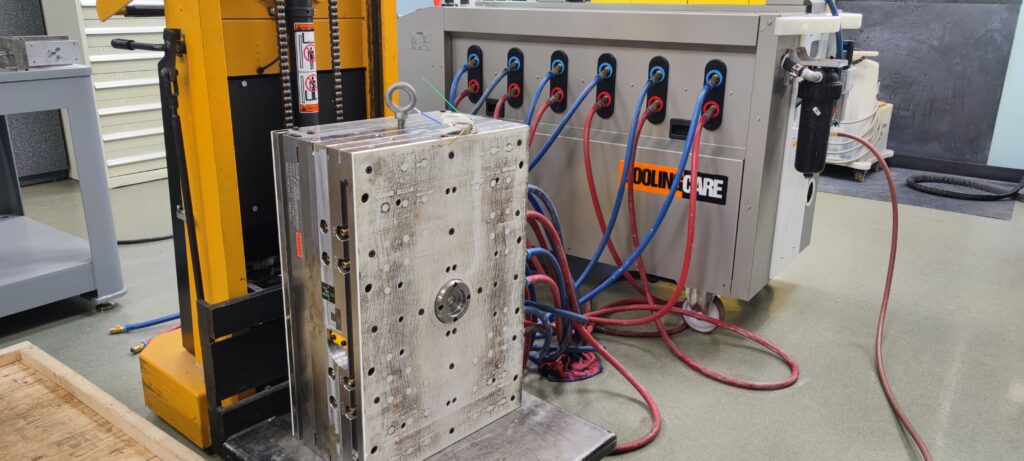

Cavitation cleaning

Patented, hybrid cleaning methodology deploying cavitation effect Cleaning method deployed in CoolingCare devices is based on the patented method of two-way pulsation of the cleaning medium. HYDRAULIC SHOCK WAVES GENERATE A CONTROLLED CAVITATION PHENOMENON THAT INITIATES THE PROCESS OF REMOVING SCALE AND RUST FROM THE CHANNEL SURFACE. Rapid compression and expansion of the liquid in […]

Operator-free, fully automatic

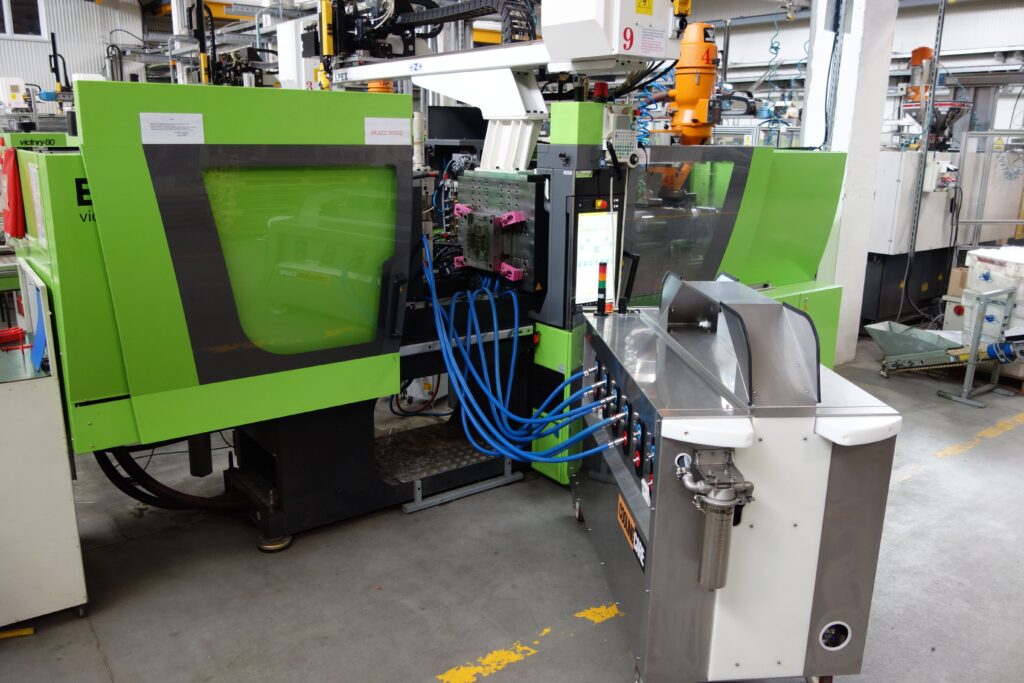

The device has been designed to minimize operator involvement. The operator’s tasks are limited to creating a new project or selecting one from the database, connecting the channels to the machine, choosing the cleaning algorithm, and pressing the START button. Automation, combined with advanced algorithms, allows the machine to execute a sequence of operations and […]

Heavy duty design

At Coolingcare, we believe that quality is not just a slogan but the foundation of every product that leaves our factory. Our cooling channel cleaning machines for injection molds are premium devices designed with reliability and maximum performance in mind. That’s why we proudly offer our customers a 3-year warranty, a testament to the top-tier […]

Process safety

It’s not uncommon for molds that require cleaning to be worth hundreds of thousands of euros. Coolingcare machines are equipped with dozens of sensors and safety algorithms that monitor the process in real time, ensuring stability of the process. In the case of sudden, unexpected event, such as i.e. leakage, the computer stops the cleaning […]

Independent cleaning sections

A separate, dedicated feed pump for every channel ensures greater efficiency and dynamics of cleaning. Many cooling channel cleaning systems on the market are equipped with a single feed pump. Such a solution creates many inconveniences that should be kept in mind when choosing a machine for channel maintenance. These include: Device efficiency – the […]

Intelligent cleaning modes

The cleaning time of the individual cooling channels may and should differ from each other, taking into account the fact that each of the channels often has a different diameter, geometry and length, which affects the generated pressure losses and therefore the cleaning time. Therefore, the method of setting the same cleaning time for all […]