About us

Innovation out of necessity

CoolingCare machines were developed as a result of more than six years of research into cleaning and diagnosing cooling channels in injection molds.

The system was developed at FADO, a company with more than 35 years of experience in the tooling and injection molding industry, specializing, among other things, in the production and design of molding inserts with conformal cooling systems. These types of channels are characterized by high geometry complexity and small diameters, and require a completely different approach, both from the operation and maintenance side.

Injection mold designs with this type of cooling, despite the obvious advantages, carry potential risks that make many companies unwilling to take the risk and invest in potentially short-term higher productivity. One of the primary criticisms leveled against conformal walking is the gradual decline in the ability to take heat from the cavity and the high susceptibility to clogging.

When the channel becomes completely clogged, there is no way to take apart the mold and unclog the circuit mechanically. Therefore, it is important to consciously monitor the status of cooling performance and apply preventive measures to maintain adequate cooling performance.

Toolroom

- Design and construction of injection molds

- Maximum mold dimensions. 500x500mm

- Machine park based on MAKINO machine tools

Injection molding plant

Injection molding machines for horizontal and vertical closing with a closing force of 10 to 800 tons. The machines are fully equipped for automatic operation.

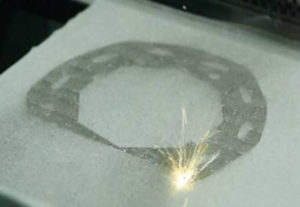

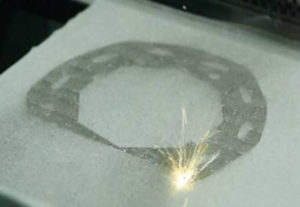

3D Printing

Laser melting technology of metal powders, production of inserts with conformal cooling, available materials: tool steel 1.2709, stainless steel 316L, AlSi10Mg, Ti64.

Toolroom

- Design and construction of injection molds

- Maximum mold dimensions. 500x500mm

- Machine park based on MAKINO machine tools

Injection molding plant

Injection molding machines for horizontal and vertical closing with a closing force of 10 to 800 tons. The machines are fully equipped for automatic operation.

3D Printing

Laser melting technology of metal powders, production of inserts with conformal cooling, available materials: tool steel 1.2709, stainless steel 316L, AlSi10Mg, Ti64.

About the company

The beginning of FADO dates back to 1984, when Jerzy Domeracki, continuing the family tradition in the tool industry, decided to start manufacturing injection molds. In a short time, thanks to determination, passion and hard work, the plant began to achieve its first successes.

The turning point in the company's history was 1991, and with it the decision to create a plastics processing department, thanks to which FADO's business model changed dramatically - the company was no longer just a tool manufacturer, it expanded its offer to include the production of plastic parts.

It turned out that the experience gained in mold design was excellent for processing work. In turn, the experience with plastic injection molding allowed even better analysis of problems and, consequently, better design of the molds themselves.

Thanks to this experience, FADO has developed many proprietary, innovative solutions that have allowed the company to build its position in the market. Commitment, continuous development and investment in new technologies have resulted in the company being honored with many prestigious awards and titles over the years, such as Forbes Diamonds, Leader of Innovation and Business Gazelles. Today, details produced at FADO can be found on most continents from all over the world.